Polymers

- Engineering

- Nov 21, 2020

- 5 min read

Updated: May 12, 2021

In this notes sheet...

Broadly, polymers (also known as plastics) are split into three types:

Thermoplastics

Thermosets

Elastomers

Each type has a specific set of properties that are dictated by its structure and the bonding within the polymer.

Polymeric Structure

All polymers consist of long macromolecules which contain chains of covalently bonded atoms. The process of turning single monomer molecules into long chains of polymers is known as polymerisation:

Polymerisation is a chemical reaction that generally happens at high temperatures with the help of a catalyst (this is to break the double bond between the carbon atoms).

The schematic above shows the polymerisation of ethylene, C₂H₄ into polyethylene (PE).

Chains are typically between 10³ and 10⁵ monomers long.

The molecular weight of the polymer is the product of the chain length and monomer weight.

Chains vary hugely in weight, and so commercial polymers are classified in terms of mean molecular weight:

The chains can be linear, branched, or cross-linked networks:

This is what dictates their properties.

Bonding

Monomers are bonded as chains with covalent bonds

Chains are connected at branches and cross-links with Van der Waals bonds

Often, hydrogen bonds form here too

Thermoplastics

As seen above, these can be regular semi-crystalline structures or amorphous (no ordered structure). The more branches there are to a chain, the less regular the structure.

We say semi-crystalline, as no polymers are truly ordered. All thermoplastics contain crystalline and amorphous regions.

The Van der Waals bonds between chains break when heated at lower temperatures than the covalent bonds holding the monomers as chains. This means they easily melt and can be formed into different shapes over and over again.

Semi-Crystalline Thermoplastics

Some of the most common examples include:

Polythene (PE)

Very cheap

Easy to mould

Tough

Generally used in bottles, packaging, pipes

Polypropylene (PP)

Same properties as PE, but stiffer

Good UV resistance

Fatigue resistance

Used as fibres, outdoor furniture, rope

Polytetrafluoroethylene (PTFE)

Excellent temperature and chemical resistance

Good non-stick properties

Used in lubricants, chemical containers & bottles, non-stick surfaces

Amorphous Thermoplastics

Common examples are:

Polystyrene (PS)

Transparent

Very cheap

Very mouldable

Brittle

Can be expanded into foam

Used for stationary, packaging, food containers, electrical insulation

Polyvinylchloride (PVC)

Cheap

Stiff but brittle

Can be expanded into foam

Used in window frames, sheeting, artificial leather, fibres

Polymethylmethacrylate (PMMA)

Transparent

Water resistant

Used for windows, laminates, surgical instruments

Thermosets

Thermosets are highly crosslinked and amorphous. They are generally formed by mixing two compounds which undergo a chemical reaction.

This reaction is irreversible, forming strong crosslinks between chains. Therefore, they do not soften or melt when heated, and cannot be reformed.

Uses for thermosets are specialist:

Epoxies are used as a matrix for fibres in composites and adhesives

Phenolics are used in motor housing, telephones, and electrical fixtures

Thermosetting polyesters are used for composites, helmets, and automotive bodies

Elastomers

Many double carbon bonds remain intact in elastomers, so there are few crosslinks between chains. This makes them extremely elastic.

The more cross links there are, the more brittle and less elastic the elastomer becomes. Elastomers do not soften or melt. They burn.

Examples of Elastomers

Natural Rubber (polyisoprene)

Harvested from the sap of the Hevea tree

Used in erasers and for latex

Synthetic Rubber (polybutadiene)

Synthesised via polymerisation

Used in car tyres

Neoprene (polychloroprene)

Used in oil resistant seals

Tensile Properties of Polymers

When a load is applied to a polymer:

Bonds may rotate

Chains may slip & disentangle

Chains may stretch

The slipping and disentanglement of chains is very easy in elastomers and thermoplastics, giving both very low stiffness and fairly low strength.

The crosslinks in thermosets, however, provide more stiffness, but at the cost of reduced toughness.

Tangent & Secant Modulus

Polymers rarely have linear sections on a stress-strain curve. As a result, the modulus cannot easily be measured as the gradient. Instead, there are two methods used:

Polymers & Temperature

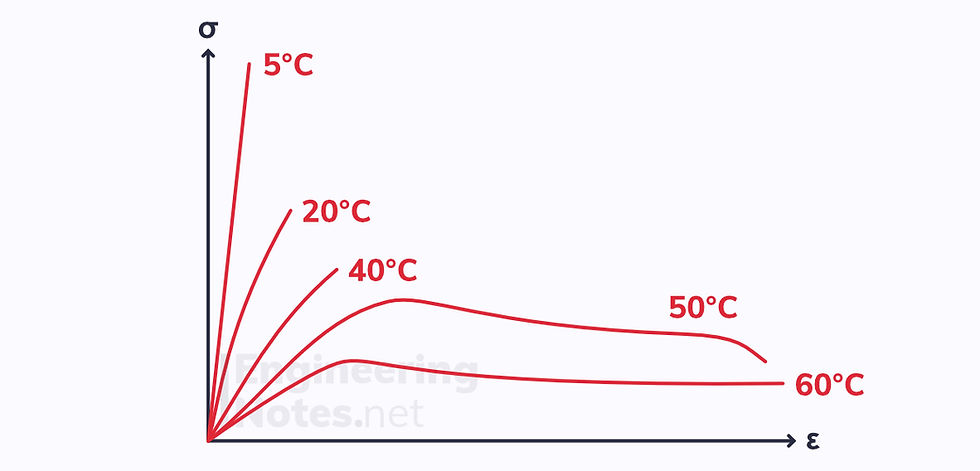

The tensile properties of polymers are often hugely dependent on temperature. Take this graph of PMMA (amorphous thermoplastic), for example:

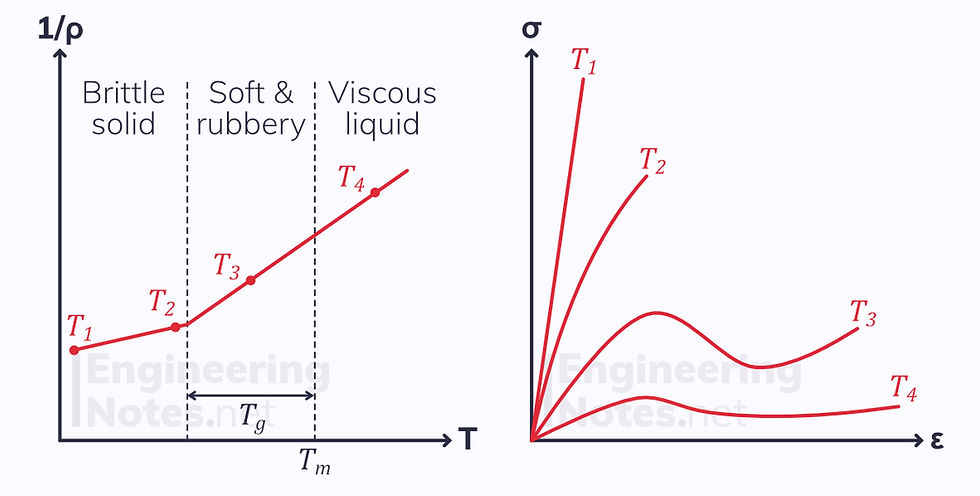

The change in properties occurs because as temperature increases, there is a change in specific volume:

At the glass transition temperature, secondary bonds between chains break apart allowing molecules to rotate (movement of side groups)

In an amorphous solid, there is free space in which the molecules can rotate, leading to a change in physical properties. Throughout the transition region, it is soft and rubbery.

Crystalline structures are incredibly dense, with little free space. The molecules have nowhere to rotate, so properties do not change in the transition region.

Semi-crystalline solids show a slight change.

Amorphous solids show a change in properties at glass transition, crystalline solids do not.

Temperature-Dependent Properties of Amorphous Plastics

Modulus of Elasticity in Thermoplastics

Modulus of Elasticity in Thermosets & Elastomers

Both thermosets and elastomers are amorphous

They show a glass transition region, but do not melt

The more cross-links there are, the higher and more temperature-stable the elastic modulus

The process of adding crosslinks is called vulcanisation – this is done by adding sulphur

Creep in Polymers

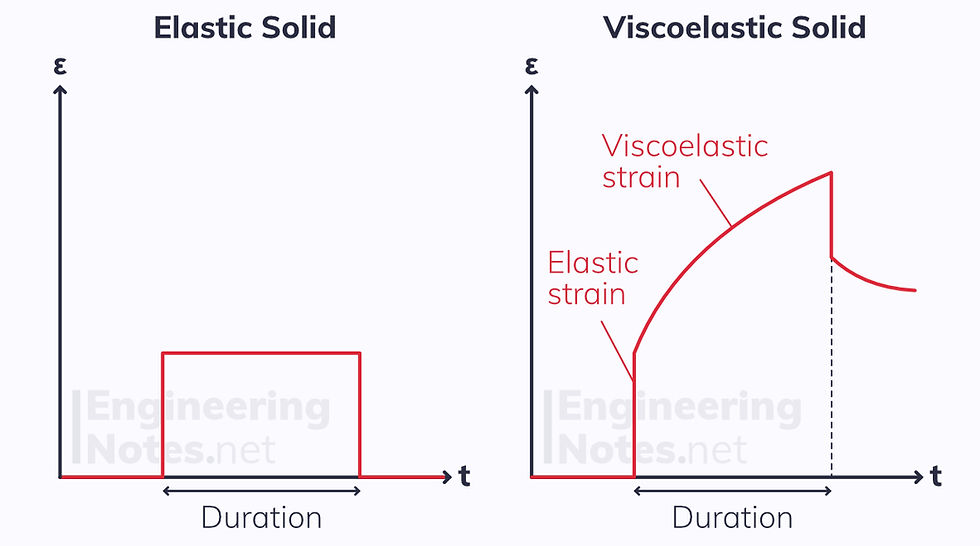

Polymers are viscoelastic solids. This means their response to instantaneous stress is two-fold: there is an immediate strain followed by a time-dependent strain.

When an instantaneous load like this is applied to both an elastic and a viscoelastic solid, the strain responses vary:

Creep in Polymers

Polymers creep at significantly lower temperatures than metals. In fact, polymeric creep is a serious issue even at room temperature, as the polymer chains uncoil so easily.

Creep is dependent on both temperature and applied stress:

The higher the temperature or stress, the faster the creep.

Unlike metals, there is no secondary steady-state creep region:

This strain response is defined by the polymeric creep law:

A and n are material constants

Creep Modulus

Since creep is dependent on stress, we can define a creep modulus as the constant applied stress divided by the strain with respect to time:

The lower the creep modulus, the easier the polymer creeps.

Failure in Polymers

Tensile Failure

The tensile failure mechanism in a polymer depends on its temperature – specifically, its temperature in relation to the glass transition temperature, Tg:

Below 0.75 Tg (in Kelvin), polymers are in the brittle, glassy region so fail by brittle fracture

This is likely to initiate at a surface defect, like a scratch of machining line

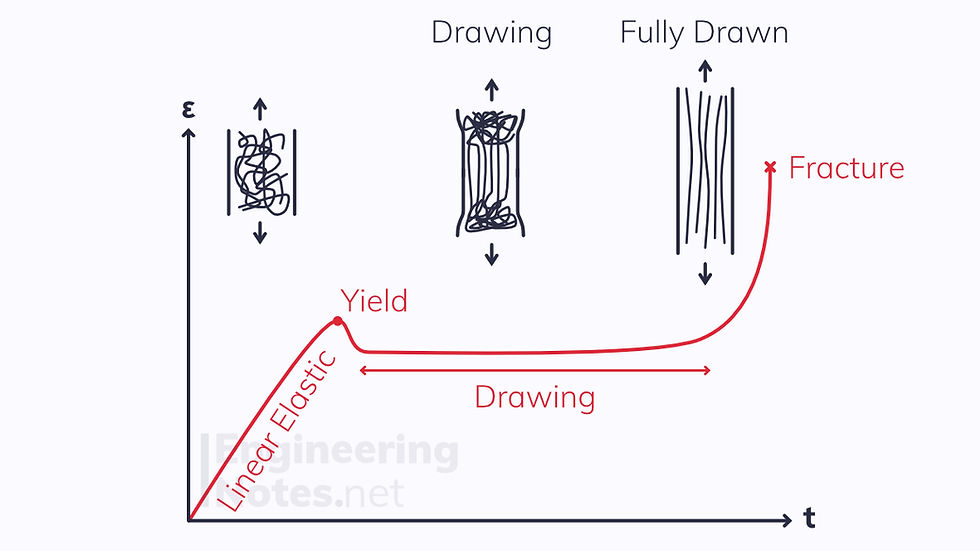

Above (Tg - 50 K), thermoplastics become plastic:

Initially, the thermoplastic deforms linearly elastically

Next, the thermoplastic yields

The thermoplastic is drawn out until all the chains are uncoiled

This massively increases the fracture strength, as at high stresses the chains are so spread out that they act as reinforcement fibres.

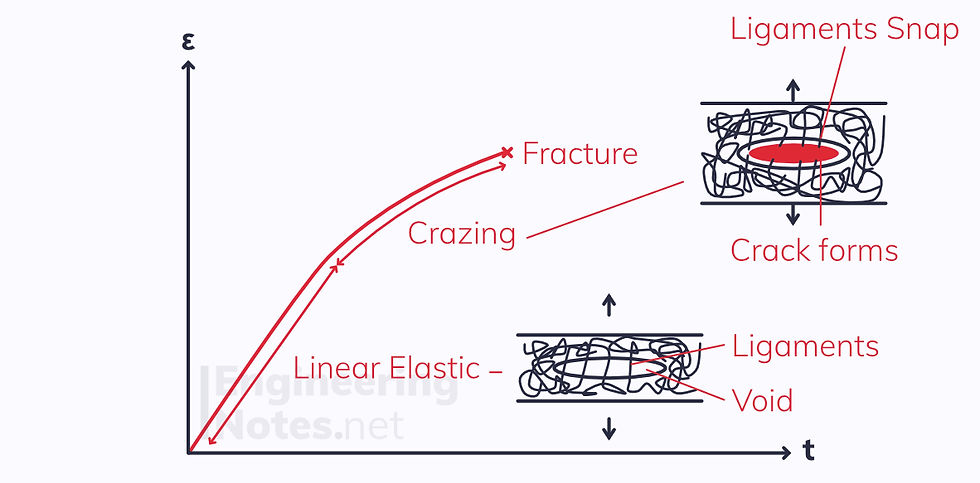

Plastics that do not draw at room temperature (e.g., polystyrene) undergo crazing:

A microvoid in the polymer is held together with ligaments across the surface

Beyond the linear elastic region, these ligaments are drawn out

Eventually, the ligaments snap, and the craze becomes a crack

Crazing is what makes plastics appear white when bent: this is known as stress whitening.

Impact Failure

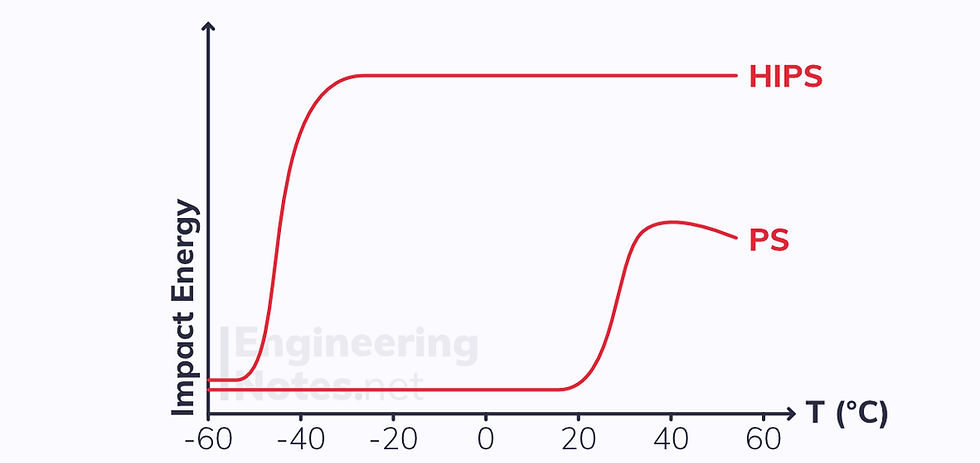

The energy required to break a polymer varies hugely with temperature, and is investigated using a Charpy impact test:

Note that modifying brittle polymers like polystyrene (PS) massively increases the energy required to break at standard temperatures: the modified plastic is called high-impact polystyrene (HIPS).

Fatigue Failure

Different polymers have vastly different fatigue behaviours. Some have fatigue limits, others do not:

Comments